The Novel Coronavirus Outbreak: Risks for India’s Pharmaceutical Industry

Amitendu Palit

1 March 2020Summary

The impact of the Novel Coronavirus has assumed enormous proportions with countries bracing themselves for substantive economic damage. Much of the damage arises from China’s prominent position in the global economy. As the world’s largest source of industrial raw materials and intermediates, imports from China are essential for the sustenance of several critical industries, such as semi-conductors, automobiles and pharmaceuticals. With China being the epicentre of the Coronavirus pandemic, many countries, including India, which have significant import dependence on China, are apprehending adverse impacts. One of India’s key concerns in this regard is the impact on its pharmaceutical industry.

India imports around 70 per cent of its bulk drugs from China, which are extensively used by its pharmaceutical industry. The key imports include heterocyclic nitrogen compounds and various antibiotics that are widely used in pharmaceutical formulations. India’s dependence on China in this regard is as a critical supplier of raw materials and intermediates for the upstream end of the pharmaceutical value chain. Upstream disruptions would adversely impact the Indian industry’s ability to manufacture generic drugs for domestic consumers and overseas markets. Anticipating such disruptions, India has restricted the exports of several bulk drugs it imports from China and their formulations. However, risks remain high for the domestic pharmaceutical industry. The lack of domestic abilities to produce bulk drugs in large scale, and the difficulties in sourcing drugs from other countries due to high global demand point to prospects of adverse impacts for Indian pharmaceutical industry, if the Coronavirus constrains drugs production within China for a long period of time.

Introduction

COVID-19, or the Novel Coronavirus, is rapidly growing into a global pandemic. Apart from human casualties, there are now serious concerns emerging on the economic damage inflicted by the pandemic. One of the major concerns among these is the impact on the global supplies of pharmaceuticals products. China is one of the world’s largest sources of raw materials and intermediates that are used by major global pharmaceutical firms for making branded and generic drugs. Countries having firms with such proficiencies, including India, have been concerned over the impact of the disruptions caused by COVID-19 on supplies of bulk drugs from China and their resultant impact on domestic availability of medicines.

This paper studies the nature of India’s drug imports from China, the dependence of its pharmaceutical industry on these imports and the likely impacts for the industry following reduced supplies from China.

India’s Drug Imports from China

India’s dependence on China for the supply of various imports – raw materials, intermediates and finished products – is significant. The largest Indian imports from China are those of machineries and components. Various electrical and non-electrical machineries, industrial appliances, machine parts and components comprise half of Indian imports from China. Among these, electrical machinery and equipment, and mechanical appliances imported from China made up around 45 per cent and 32 per cent respectively of total such imports by India during the year 2018-19.

Beyond mechanical and engineering products and parts, India relies heavily on China for chemical imports. The most important among these are organic chemicals and fertilisers. With a share of around 12 per cent in India’s total imports from China, organic chemicals are the third largest group in the latter. As mentioned earlier, for mechanical products and parts, India’s organic chemical imports from China were around 38 per cent of its total organic chemical imports during 2018-19.

Within organic chemicals, two groups of products are particularly significant. These are heterocyclic nitrogen compounds and antibiotics, various items of both of which are extensively used by the Indian pharmaceutical industry.

The prominence of these imports in India’s overall imports from China is striking. At around US$1.4 billion (S$1.95 billion) and US$1.1 billion (S$1.53 billion) respectively, nitrogen compounds and antibiotics accounted for almost 30 per cent of India’s total organic chemical imports of US$8.5 billion (S$11.86 billion) from China in 2018-19. These two organic chemical sub-group of imports accounted for two per cent and 1.5 per cent respectively of India’s total imports of US$70.3 billion (S$98.1 billion) from China in 2018-19. Furthermore, India’s imports of nitrogen compounds and antibiotics from China are 69 per cent and 76 per cent of its total such imports. This reveals the high degree of dependence India has on China for these products. Indeed, the shares of imports of these products from China in India’s total imports of such products is higher than most of India’s major imports from China.

India’s largest imports from China are electrical products and components. It sources 43 per cent of its total requirement of these items from China. Automatic data processing machines and units, electronic circuits, and diodes and conductors are India’s other most prominent imports from China. It sources 47 per cent, 32 per cent and 63 per cent respectively of its total requirements of these items from China.

A close look at the characters of the two prominent groups of imports underlines the reasons for the anxieties regarding the prospects of Indian pharmaceutical industry following supply disruptions. Heterocyclic nitrogen compounds contain carbon and nitrogen in their molecular structures and have extensive therapeutic use. The compounds are used extensively in pharmaceutical research and drug discovery. They are also significant in production of antibiotic formulations, and in anti-cancer, anti-migraine, anti-ulcer, anti-inflammatory, anti-viral and anti-depressant drugs. Antibiotics imported from China are widely used in the preparation antibiotic formulations for retail sale. Both products have extensive use as bulk drugs in India’s pharmaceutical industry. During the last five years, that is, from 2014-15 to 2018-19, India’s imports of both from China have remained significant (Figure 1; refer to in PDF version).

While around 70 per cent of India’s total imports of heterocyclic nitrogen compounds are from China, 80 to 90 per cent of the entire requirements of some among these items, such as those with unfused rings, are sourced only from China. Among antibiotic imports, the most significant ones are penicillin and its salts, rifampicin and its salts, 6-APA,2 and various other antibiotics. More than 90 per cent of penicillin and its salts are imported by India from China, whereas practically all 6-APAs are only imported from China. Around 70 per cent of rifampicin salts are imported from China too (Figure 2; refer to in PDF version).

India, China and the Pharmaceutical Value Chain

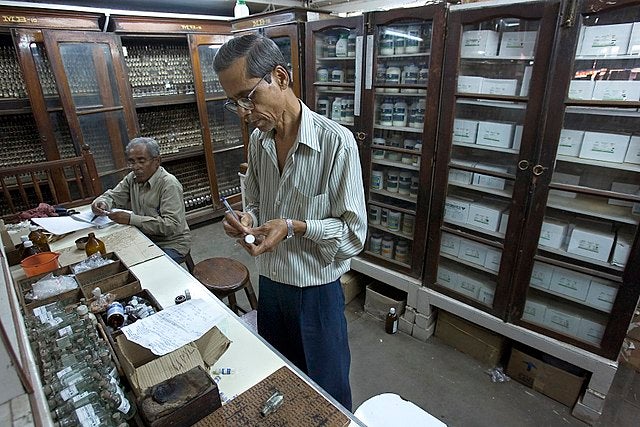

The various antibiotic and heterocyclic nitrogen compound imports from China connect China and India closely in the pharmaceutical value chain. In this regard, India’s significant reliance on specific imports from China underlines a specific character of the value chain and the roles of Indian and Chinese producers therein. India’s pharmaceutical imports from China are essentially in the form of bulk drugs. Antibiotic bulk drugs, for example, are in powder form and need to be processed into formulations for final consumption. Once processed as capsules or tablets, the particular bulk drug, which is the most prominent constituent of the composition, becomes its active pharmaceutical ingredient (API). Over the years, Indian pharmaceutical companies have achieved great proficiency in making formulations, their packaging and retail marketing. Such proficiencies have led to Indian pharmaceutical companies becoming the world’s leading producer of generic drugs, which are cheaper formulations of branded drugs, once they go off-patent. Generic drugs manufactured by various Indian firms – Lupin, Dr. Reddy’s Laboratories, Ranbaxy, Sun Pharma, Torrent, Glenmark and many others – have obtained deep access in various global markets, given the price competitiveness of Indian generic formulations. However, the success has been largely enabled by the availability of cheap bulk drugs from China.

From a value chain perspective, the downstream proficiencies of Indian pharmaceutical industry would have remained unutilised had it not been able to import the upstream raw drugs from China for use as APIs in formulations. Both heterocyclic nitrogenous compounds, as well as various antibiotics, like penicillin and rifampicin salts, are used in different pharmaceutical formulations. The nature of the value chain in this regard, possesses striking similarities with the petroleum and automobile value chains. For both these value chains, Indian firms have developed commendable expertise at the downstream levels: in producing refined petroleum products and passenger and commercial vehicles respectively. For both though, the reliance on upstream imports is significant. The refined petroleum industry is heavily dependent on the import of crude oil, while the automobile industry is dependent on parts and components from abroad. In recent years, India has begun emerging as an important global location for assembling smartphones, where again, a similar tendency of relying on imported components is noted.

The pharmaceutical industry’s dependence on imported intermediates would have been much less had the same products been available at home. Unfortunately, several key APIs, including penicillin-G, streptomycin and tetracycline are not available in India. For many others, the lack of scale on the part of domestic manufacturers and the relatively higher cost of indigenously produced APIs make imported APIs from China much preferred options for formulation makers, in both volume and value.

Impact of Import Disruptions

Given the heavy dependence of the Indian pharmaceutical industry on bulk drugs from China, there are legitimate concerns over the adverse impact on domestic pharmaceutical production, as supplies from China get affected due to the outbreak of COVID-19. The concern is not just an apprehension for India. It is as much a concern for formulation drug makers in the US and other countries that depend on APIs from China. For Indian pharmaceutical producers, the impacts would not be limited to their ability to supply the large domestic market, but also ability to supply global markets through exports.

The scale of disruption caused by COVID-19 was unexpected. Many of the economies of the world, including Indian pharmaceutical industry, has been taken by surprise by the scale of the pandemic, both in terms of its spread across borders, as well as the contraction of economic activity within China. The Indian pharmaceutical industry, as a result, has not been able to keep sufficient stocks of imported bulk drugs. Most pharmaceutical companies retain bulk drug stocks of up to six weeks. Beginning mid/late January 2020, the time from when COVID-19 begun assuming highly fatal proportions in China with serious impact on domestic production and supply of imports, the inventories with Indian producers should last up to February/March 2020 for most drugs they use in formulations. Thereafter, however, if supplies dry up, formulation production would be affected. There are already some signs of panic creeping in with the prices of some common formulations, such as those using paracetamol as API in common over-the-counter formulations like crocin and pyrigesic, beginning to rise, in anticipation of their foreseeable low domestic availabilities.

Indeed, even before an actual decline in imports of bulk drugs, supply disruptions are likely with shipments arriving from China facing clearance issues at Indian ports. Containers arriving from different Chinese ports are lying unloaded or facing long delays in offloading at Indian ports as the necessary documents for obtaining cargo clearance at Indian customs are taking too long to arrive from China. By getting stuck in Indian ports, bulk drug supplies are failing to replenish existing stocks – a problem that is likely to aggravate if COVID-19 sets in deeper in China.

What are the options available before India for managing the supply disruption? So far, there have been two precipitate actions. The Department of Pharmaceuticals in the Ministry of Chemicals has recommended restricting exports of around a dozen APIs that India imports from China, and their formulations, following suggestions by an expert committee set up by the ministry. The ostensible idea is to preserve as much of the APIs and their final products for domestic consumption as possible. At the same time, there are efforts to ramp up domestic production of bulk drugs on which India’s dependence on imports from China is critical. However, these efforts are yet to formalise into a specific strategy. Even if a formal strategy is put in place quickly, the results are going to become visible only much later. Achieving higher volumes of bulk drugs at competitive prices at home from producers crippled by the lack of scale and difficult business conditions is a tall task.

The other option for India is to explore the possibility of sourcing the APIs it obtains from China from other countries. Nitrogenous compounds and antibiotics are prominently exported by some European countries – Ireland, Belgium, Switzerland – and the United States. It is not going to be easy to effect a quick switch though. The global demand for bulk drugs from non-China locations is going to increase rapidly as more and more countries turn to other locations to make up deficient supplies from China. The higher demand is going to impact bulk drug supplies and prices, reflecting in a concomitant impact on prices of formulations.

India faces the prospect of disruptions in domestic availability and export of generic drugs and formulations as it visualises the imminent possibility of bulk drug and intermediate supplies from China choking off. This is an unavoidable outcome of the character of the pharmaceutical value chain that embeds Indian pharmaceutical producers and consumers to China in an inextricable manner. The economic impact of production cutbacks in China following COVID-19 and its rapid spread would extend significantly to the rest of the world, including India.

. . . . .

Dr Amitendu Palit is a Senior Research Fellow and Research Lead (Trade and Economic Policy) at the Institute of South Asian Studies (ISAS), an autonomous research institute at the National University of Singapore (NUS). He can be contacted at isasap@nus.edu.sg. The author bears full responsibility for the facts cited and opinions expressed in this paper.

-

More From :

More From :

-

Tags :

Tags :

-

Download PDF

Download PDF